Through custom-made guitars | Part 2 – Background and production process

- 2017.12.16

- 著者:Isaku

I would like to consider various things through the experience of ordering a guitar. The second part describes the background and production process.

Previous Article – Part 1 covered the specifications of custom-made guitars.

This time, I’ll write about the process and history.

目次

Preface

The first time I held an electric guitar was when I was in junior high school.

It was a cheap one that looked similar to ESP’s MAVERICK.

When I entered high school, my parents bought me a Gibson Les Paul Studio as a celebration gift, and I really liked it and used it a lot, but I was concerned about its weight and how easily it went out of tune.

When I bought a Fender USA Thin Line, I was bothered by the noise and changed the pickups myself.

I also shaved the thick neck myself.

However, I was bothered by the small frets and difficulty in chording.

When I bought Gretsch’s Tennessee Rose or Silver Jet, I was bothered by the difficulty of playing in the high positions, and with Fujigen’s Mustang, I was bothered by the sound of the pickups and the pitch, and with Gibson’s SG, I was bothered by the thickness of the neck, the low frets, and the pegs, and with Godin’s Acousticaster, the circuit…

I tried various things each time.

From the moment I picked up the guitar, I didn’t often find one that perfectly matched my preferences.

Having preferences is endless, but as I tried various guitars, I began to understand my preferences.

Ideal Guitar Concept

Since I had various experiences, I wanted to see what would happen if I made something that incorporated all of my ideals.

List by Element

First, I listed my requests from the neck to the circuit and created composite images for reference.

Ver1.0

Ver1.0

A Telecaster-shaped relic with 25 frets.

Next, I created reference photos with measurements closer to reality.

Ver1.1

Ver1.1

At one point, the design changed, and it ended up with 23 frets.

Ver1.2

Ver1.2

I also created variations in appearance.

Although the appearance didn’t quite fit, the specifications (spec sheet) were revised several times and settled.

※Ideally, you should finalize the specifications before creating the appearance, but it’s okay to create an image diagram when you’re unsure.

How to Make It

At first, I thought about getting a ready-made guitar and modifying it in various ways.

Since I wanted a guitar with traditional Strat-like features, I thought about modifying a Stratocaster.

Body Shaping Proposal

This is a bit… I ended up with something I don’t quite understand.

Custom Made

At that time, I consulted with my longtime friend, Mr. Hata (High-End Music), who suggested, “It might be better to go for a full custom order.”

Also, he had plans to make a model for a regular line separately, and it would be helpful for us to support that by making a custom guitar and providing feedback, so I decided to commission it as a job.

Manufacturing Process

First, I completely fixed the specifications and created reference photos as usual.

To determine the appearance properly, I set a concept and used it as a guide.

Ver2.0

Ver2.0

Almost Final Form. At this point, if there is a significant deviation from the final form, it means my direction skills are very poor.

During production, it is important to avoid saying “Let’s change it.”

The guitars I referred to were Fender Telecaster, Tom Anderson Short Hollow T, Strandberg Boden J6 Standard, and others.

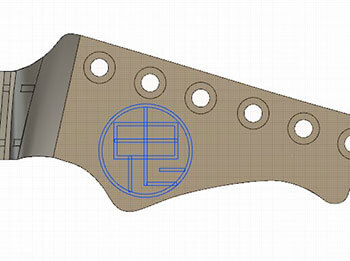

Modeling and Processing

A 3D model was created based on the specifications. As you can see, it’s a chambered body.

With a 94% downsized body, even small people can hold it comfortably.

Body

The body is coming along. It’s a technically challenging drop-top specification.

Fingerboard Material

I wanted the fingerboard material to be the main accent, but I couldn’t find one that I liked locally.

Then, Mr. Hata sent me a photo.

It’s a wonderful material. The fingerboard is now decided.

The fret slots, truss rod, and inlays are finished, and the neck is coming along.

With a very slim neck, it has a comfortable fit that is easy for people with large hands to handle.

The final form is becoming visible.

For the fan fret, a dedicated bridge is usually used, but a Wilkinson VS100N 6-string was slightly modified to fit.

The joint uses a special 4-point structure.

Although I searched for pickguard materials such as ziricote and bubinga, I couldn’t find one I liked.

However, I found a slightly different translucent tortoiseshell one, so I decided to use that.

The frets have been installed. As usual, the edges are rounded for a comfortable feel in the hand.

A Buzz Feiten tuning system is also installed.

Pickup Covers

It’s purely for appearance, but I wanted to match the color of the pickup covers to resemble traditional 2-single pickups.

Since “wood can be used to make covers,” I decided to use fingerboard material.

All pickups are Suhr ML.

The painting and sanding are complete. There are slight streaks remaining.

The color is black lacquer, but even black has various shades depending on the manufacturer.

This time, it turned out to be a very deep jet black.

Headstock

The demon logo on the headstock is made of abalone.

Since it has a zero fret, a tension bar was added.

Assembly of parts is complete, and the guitar is finished.

Impressions

The finished guitar, with all my ideals packed into it, is a perfect piece with no complaints.

When I first held it, I felt unfamiliar with the fan fret and the freshness of something I had never experienced before, but I quickly got used to it within a few days.

Both playability and sound from the amp are excellent.

Although I wrote this quickly, the production process involved a lot of steps and each one required effort and demanded considerable precision.

I posted a short tune 😃

This time, I mainly wrote about the process and history.

In the next sequel, I’d like to delve into analysis and summary.

Postscript: I wrote it. Click here for the next sequel.